Fan heater - NW 50 AGRO | Flowair

Select the product model:

Arvydas Palivonas

LT, RU, EN+370 601 74426

Sales representative for Vilnius, Ukmergė, Utena, Kaišiadorys and Varėna regions Get Offer

Andrius Lekarevičius

LT, RU, EN+370 606 11865

Sales representative for Kaunas, Panevėžys, Šiauliai, Telšiai, Klaipėda, Tauragė, Marijampolė and Alytus districts Get Offer

- Models specifications

- Technical data

- Description

- Documentation

- Accessories, related items

- Gallery, installation examples

- Download PDF

| LEO AGRO - resistant to dust and water (IP66) axial fan, easy cleaning, dedicated for aggressive environments |

|---|

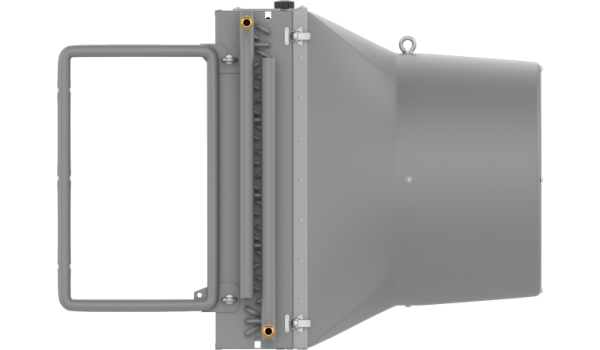

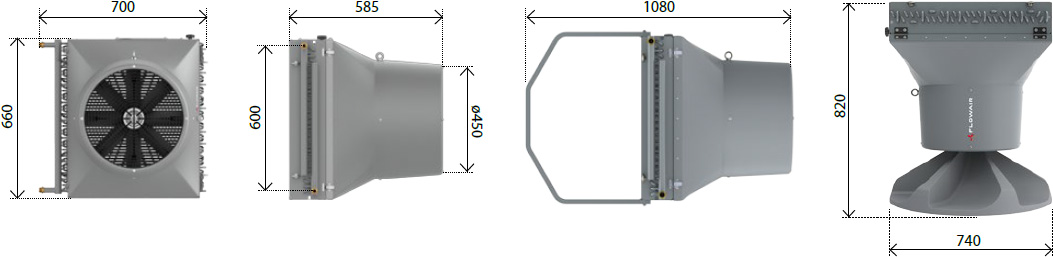

Dimensions

Heating capacity tables

- PT - heating capacity

- Tp1 - air temperature at the unit inlet

- Tp2 - air temperature at the unit outlet

- Tw1 - heating medium temperature at the heat exchanger inlet

- Tw2 - heating medium temperature at the heat exchanger outlet

- Qw - heating medium flow rate in heat exchanger

- Δpw - heating medium pressure drop in heat exchanger

If you want to calculate heating capacity at different parameters you can do this at manufacturer website.

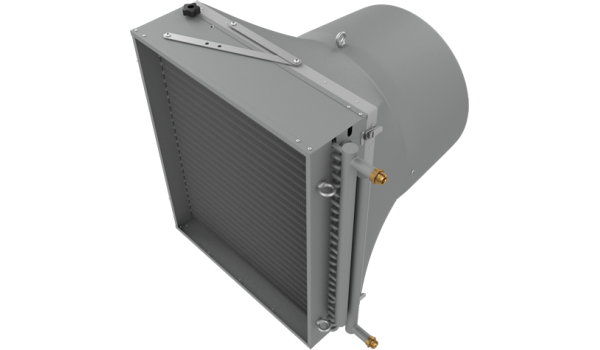

LEO AGRO fan heaters are specially designed for aggressive conditions and well-suited for heating of large areas where dust, high humidity and chemicals based corrosive exposure is present, e.g. poultry, pig, cattle and stud farms, washing and drying sites, waste water treatment areas, etc. LEO AGRO heaters are non-inertial: high capacity enables fast and uniform heating of premises; safe and easy to clean. LEO AGRO fan heaters are manufactured of three different casings: 1) metal casing, 2) plastic casing and 3) openable casing.

1) LEO AGRO ST metal casing is made of zinc steel coated with anticorrosive layer, resistant to abrasion, heat, cold, corrosion and weather conditions. Specific heat exchanger is epoxy and special anticorrosive layer coated. Larger gaps between heating fins (4 mm) as well as thicker heating fins make easy cleaning of impurities with high pressure washing equipment. Washing process causes no deformation to heating fins, and drain plugs installed at the top and bottom of heater casing provide easy removal of water accumulated in the casing. LEO AGRO heaters are recommended to use in large areas of high ammonia concentration (up to 25 ppm), high air dust and humidity level: in chicken farms, sawmills, car wash sites, pools.

1) LEO AGRO ST metal casing is made of zinc steel coated with anticorrosive layer, resistant to abrasion, heat, cold, corrosion and weather conditions. Specific heat exchanger is epoxy and special anticorrosive layer coated. Larger gaps between heating fins (4 mm) as well as thicker heating fins make easy cleaning of impurities with high pressure washing equipment. Washing process causes no deformation to heating fins, and drain plugs installed at the top and bottom of heater casing provide easy removal of water accumulated in the casing. LEO AGRO heaters are recommended to use in large areas of high ammonia concentration (up to 25 ppm), high air dust and humidity level: in chicken farms, sawmills, car wash sites, pools.

2) LEO AGRO CR – plastic casing, heat exchanger is anticorosive layer coated. It has thicker heating fins with larger gaps between them (4 mm). Most suitable for high humidity and average pollution premises, such as: car washes, swimming pools, greenhouses. It can be washed with high pressure washing equipment.

2) LEO AGRO CR – plastic casing, heat exchanger is anticorosive layer coated. It has thicker heating fins with larger gaps between them (4 mm). Most suitable for high humidity and average pollution premises, such as: car washes, swimming pools, greenhouses. It can be washed with high pressure washing equipment.

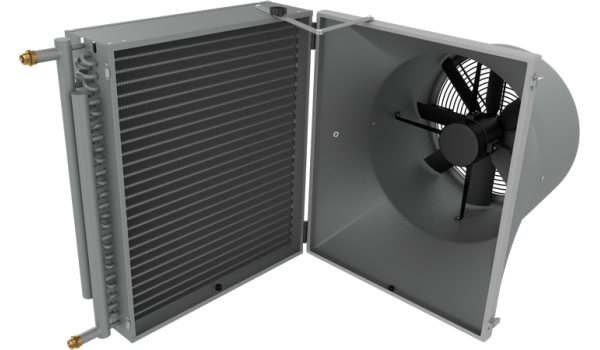

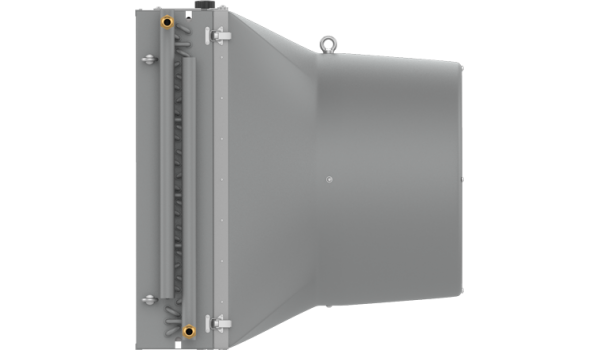

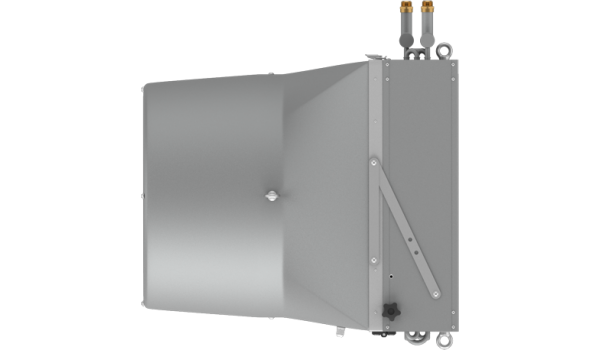

3) Key advantage of LEO AGRO SP and HP is easy-to-open casing which ensures easy access to heat exchanger for cleaning from both sides. Fan in LEO AGRO SP and HP models is located in the front part of the heater, and it directs heat from heat exchanger to the premises at the distance of 28 m.

3) Key advantage of LEO AGRO SP and HP is easy-to-open casing which ensures easy access to heat exchanger for cleaning from both sides. Fan in LEO AGRO SP and HP models is located in the front part of the heater, and it directs heat from heat exchanger to the premises at the distance of 28 m.

SP model heat exchangers are epoxy coated; they are designed for aggressive environment such as poultry farms and drying sites. SP models as standard LEO AGRO ones can be applied in areas of high ammonia concentration (up to 25 ppm).

HP model heat exchangers are coated with several layers of special anticorrosive paint and are designed for heating of EXTREMELY severe areas: pig farms and waste water treatment areas. Heaters are resistant to major corrosive compounds; they also can be cleaned by pressurized air or flushed by high pressure washing equipment.

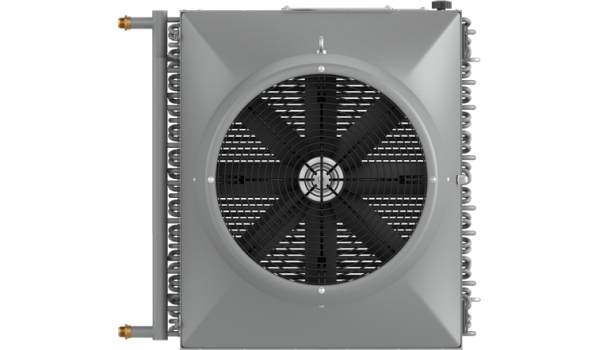

All LEO AGRO models are equipped with IP66 protection class fans with thickened plastic blades which are more wear-resistant. Fan design allows the increasing loads (e.g. exchanger contamination with dust) to effect its performance as less as possible.

The advantages of LEO AGRO fan heaters:

- Heaters are developed and produced by company FLOWAIR. This company specializes in production of such type of heaters only and is the number one in a competitive Polish market!

- Designed for aggressive environment, agriculture – high quality parts, resistance to chemical exposure, humidity, dust and corrosion.

- IP66 fan. Such fans with thickened plastic blades are suitable in the areas full of dust or humidity.

- Easy to clean – heater dismantling is not needed; it can be cleaned by pressurized air or water. Larger gaps between heat exchanger fins which are thickened to prevent deformation when cleaning.

- Quality guarantee – European product with technical properties meeting the declared values, CE certified.

- Easy to install. Light weight and specific mounting brackets make LEO AGRO fan heaters easy to install.

- Extensive application: poultry, pig, cattle and stud farms, slaughterhouses, sawmills, car wash sites, greenhouses, pools, drying sites, waste water treatment areas and other facilities with potential air pollution and high humidity.

Heating equipment

Heating equipment Fan heaters

Fan heaters Gas heaters

Gas heaters Air curtains

Air curtains Hot water

Hot water Ambient

Ambient Gas fired

Gas fired Fan coils

Fan coils Wall mounted

Wall mounted Concealed

Concealed External gas heaters

External gas heaters Infrared heaters

Infrared heaters Electric

Electric Gas - radiant tube

Gas - radiant tube Heat pumps

Heat pumps Gas

Gas Destratification fans

Destratification fans Gas radiators

Gas radiators Gas boilers

Gas boilers Electric heaters

Electric heaters Diesel fired heaters

Diesel fired heaters Containers and drums heating

Containers and drums heating IBC containers heaters

IBC containers heaters Drum heaters

Drum heaters Gas cylinders heaters

Gas cylinders heaters Heating blankets and mats

Heating blankets and mats Ventilation equipment

Ventilation equipment Ventilation components

Ventilation components Anemostat diffusers

Anemostat diffusers Air grilles

Air grilles Wall grilles

Wall grilles Air-flow grilles

Air-flow grilles Floor air grilles

Floor air grilles  Doors air grilles

Doors air grilles Spiral grilles

Spiral grilles Egg crate grille

Egg crate grille Pressed air grilles

Pressed air grilles Metal-mesh air grilles

Metal-mesh air grilles Perforated air grilles

Perforated air grilles Low-velocity diffusers

Low-velocity diffusers Louvre systems / Regulating louvres

Louvre systems / Regulating louvres External intake louvres

External intake louvres External exhaust louvres

External exhaust louvres Roof units

Roof units Intake & Exhaust louvres

Intake & Exhaust louvres Roof bases

Roof bases  Cylindrical roof exhaust

Cylindrical roof exhaust  Under-window air valves

Under-window air valves Plenum box

Plenum box Dampers

Dampers  Duct dampers

Duct dampers  For grilles & diffusers

For grilles & diffusers Cooling equipment

Cooling equipment Evaporative air coolers

Evaporative air coolers Dry coolers

Dry coolers Remote condensers

Remote condensers