Condensing and modulating gas fired unit heater - G | Robur

Arvydas Palivonas

LT, RU, EN+370 601 74426

Sales representative for Vilnius, Ukmergė, Utena, Kaišiadorys and Varėna regions Get Offer

Andrius Lekarevičius

LT, RU, EN+370 606 11865

Sales representative for Kaunas, Panevėžys, Šiauliai, Telšiai, Klaipėda, Tauragė, Marijampolė and Alytus districts Get Offer

- Models specifications

- Technical data

- Description

- Documentation

- Accessories, related items

- Gallery, installation examples

- Download PDF

| G series - patented Robur heat exchanger in aluminium special alloy with Ground Effect, additional condensing heat exchanger, Pre-Mix burner technology, axial fan |

|---|

| G 30 | G 45 | G 60 | G 100 | |||

| Heat input | max. | kW | 30 | 45 | 58 | 93 |

| min. | kW | 15 | 15 | 19.3 | 31.7 | |

| Nominal heat output | max. | kW | 29.2 | 43.3 | 56.2 | 90.2 |

| min. | kW | 12.6 | 15.6 | 20.2 | 33.5 | |

| Efficiency | max. output | % | 97.3 | 96.3 | 97.0 | 97.0 |

| min. output | % | 105.3 | 104.3 | 104.6 | 105.7 | |

| Gas consumption1 | natural gas | m3/h | 3.17 | 4.76 | 6.14 | 9.84 |

| LPG | kg/h | 2.33 | 3.50 | 4.53 | 7.26 | |

| Airflow rate2 | max. | m3/h | 2700 | 4000 | 5350 | 8250 |

| min. | m3/h | 2300 | 2340 | 3310 | 5200 | |

| Temperature rise | at maximum speed | °C | 31.1 | 31.8 | 30.8 | 32.1 |

| at minimum speed3 | °C | 16.3 | 19.6 | 17.9 | 18.9 | |

| Gas connection | ”M | 3/4" | ||||

| Air inlet pipe diameter | mm | 80 | ||||

| Exhaust flue pipe diameter | mm | 80 | ||||

| Electrical supply | 230 V 1N - 50 Hz | |||||

| Installed wattage | W | 350 | 450 | 750 | 900 | |

| Air throw at maximum speed in free field4 | m | 10 | 25 | 31 | 40 | |

| Recommended height of installation | m | 2.5 | 2.5-3 | 3-3.5 | 3-4 | |

| Operating temperature range5 | °C | 0-35 | ||||

| Sound pressure level at the max speed at 6 meters distance | in open field | dB(A) | 47 | 48 | 50 | 54 |

| in typical installation | dB(A) | 59 | 60 | 61.5 | 65.5 | |

| Sound pressure level at the min speed at 6 meters distance | in open field | dB(A) | 42 | 43 | 45 | 49 |

| in typical installation | dB(A) | 54 | 55 | 56 | 60.5 | |

| Dimensions | width | mm | 656 | 706 | 796 | 1296 |

| depth | mm | 735 | 735 | 760 | 740 | |

| height | mm | 800 | ||||

| Weight | kg | 55 | 66 | 76 | 122 | |

- At 15 °C - 1013 mbar.

- At 20 °C - 1013 mbar.

- Temperature rise of the air which permits to maintain the outlet air flow at a higher temperature than the one of the human body for a better comfort.

- Throw for guidance only. Throw depends on height of building, mounting height to heater, room temperature and louvre setting.

- Indoor temperature of the installation location. The unit’s internal components have been tested from 0°C to 60°C.

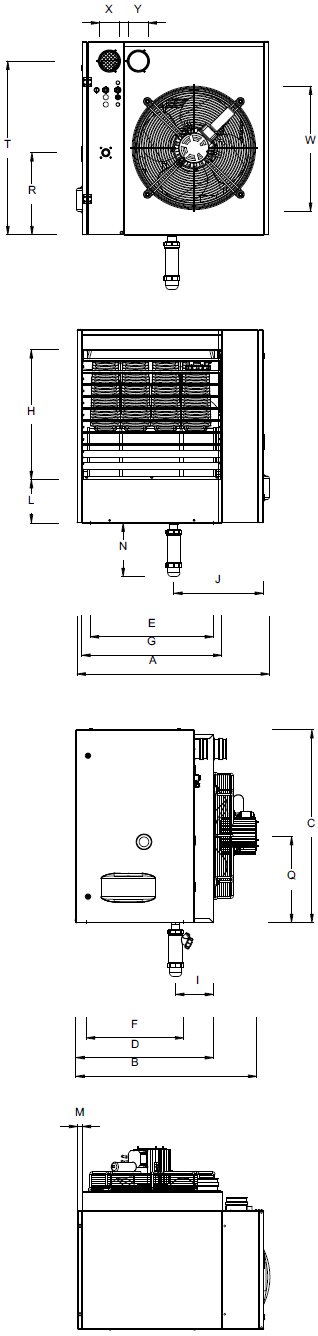

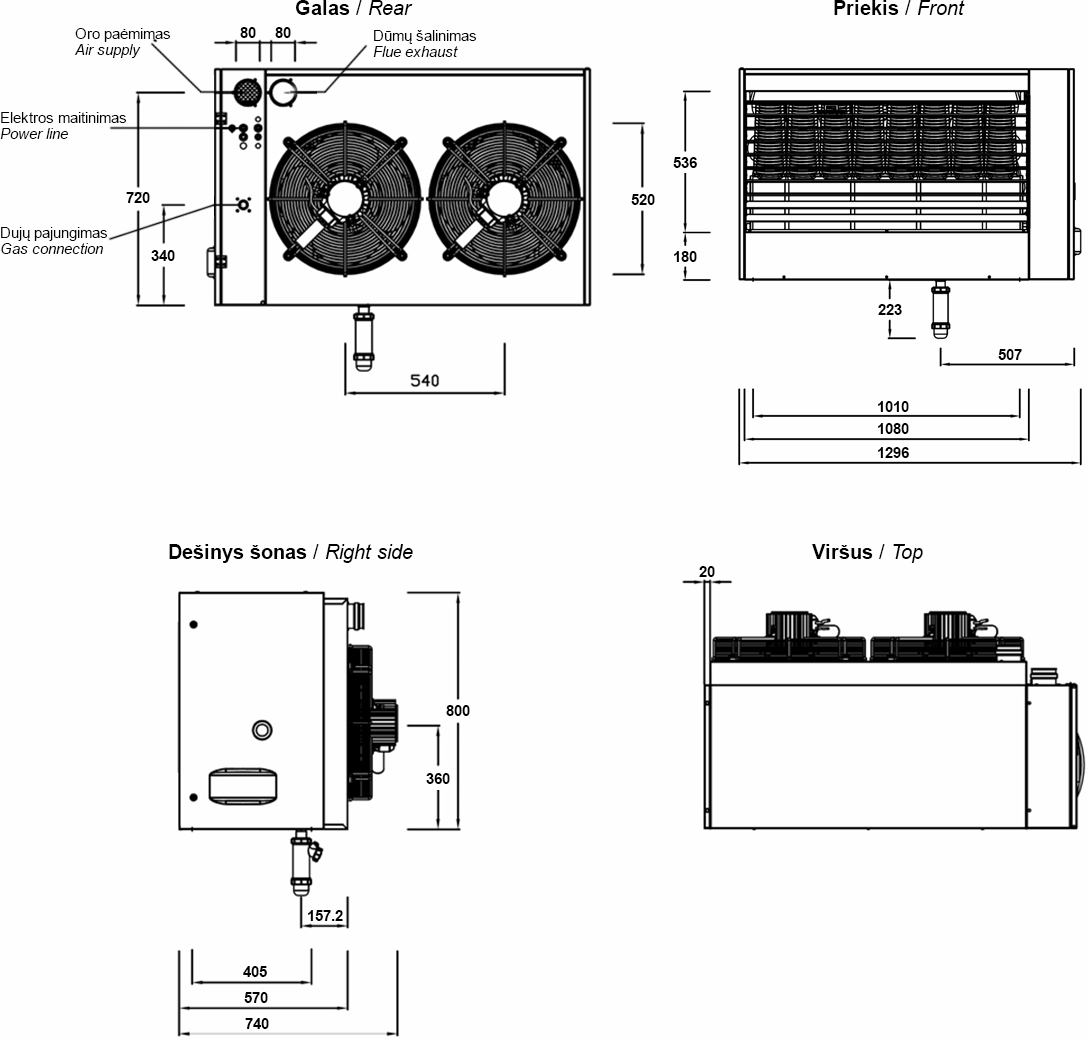

Dimensions

| G 30 / G 45 / G 60 | G 100 | |

|

Back view |  |

| Front view | ||

| Right side view | ||

| Top view |

| A | B | C | D | E | F | G | H | I | J | L | M | N | Q | R | T | W | X | Y | |

| G 30 | 656 | 735 | 800 | 570 | 370 | 405 | 440 | 536 | 157.2 | 307 | 180 | 20 | 223 | 360 | 340 | 720 | 400 | 80 | 80 |

| G 45 | 706 | 735 | 800 | 570 | 370 | 405 | 490 | 536 | 157.2 | 327 | 180 | 20 | 223 | 360 | 340 | 720 | 520 | 80 | 80 |

| G 60 | 796 | 760 | 800 | 570 | 510 | 405 | 580 | 536 | 157.2 | 371 | 180 | 20 | 223 | 360 | 340 | 720 | 520 | 80 | 80 |

| G 100 | 1296 | 740 | 800 | 570 | 1010 | 405 | 1080 | 536 | 157.2 | 507 | 180 | 20 | 223 | 360 | 340 | 720 | 520 | 80 | 80 |

It is not an easy task to find a really effective way for heating of commercial and production premises of medium or large areas; a way, which would render comfort and be economic. The heating & cooling company ROBUR with its business run all over the world, and with its long-lasting experience in the production and supply of heating equipment throughout Europe, has things to offer. The products of this Italian company demonstrate technological progress, which helps saving energy resources and brings benefit to people.

ROBUR offers the new-generation condensing and modulating gas fired unit heaters – model G – as one of the most effective ways of heating with natural or liquefied petroleum gas (LPG). These are the heaters that can achieve the efficiency of as much as 105% and reduce energy consumption by up to 25% in comparison to other heaters of this type. The tests performed by ROBUR Research and Development Center as well as the units installed all over Europe have proved that series G gas fired unit heaters are capable of warming up a medium or large area premise (a factory shop, workshop, warehouse, sports hall, health care center, indoor tennis court, bowling alley, laboratory, greenhouse, etc.) within 30 min. The modulation functions in the heater allow increasing the level of comfort. This means that the heating power can be adjusted in the range of 40% to 100%, and that the stream of the air coming from the fan can be set for operation at any of the three available speeds; e.g., the unit starts at its maximum capacity and warms up the premise within short time; later on, it reduces the power and undertakes keeping the temperature at the required (desired) level only. This allows higher efficiency, larger energy savings and more comfort to people and the environment.

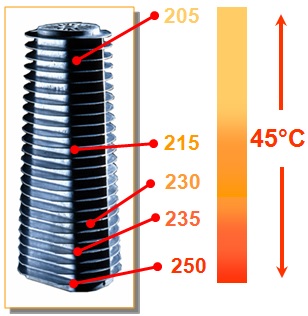

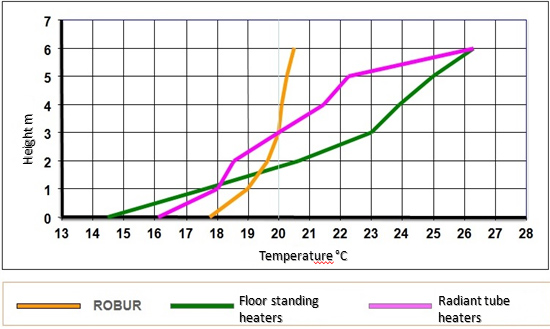

Fig. 1: Temperature distribution in the pyramid-shaped heat exchanger

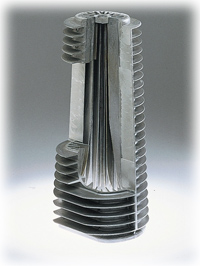

The key secret of the high efficiency of the air heaters from ROBUR is a special proprietary heat exchanger in aluminum alloy with ‘Ground Effect’. The thermal conductivity of aluminum alloy is higher than the thermal conductivity of steel by as many as 10 times. This renders homogeneous, evenly distributed temperature over the surface of the heat exchanger. The pyramid-shaped heat exchanger distributes an air stream to different temperature layers: higher temperature is kept at lower levels and vice versa (see Fig.1). So, therefore, colder air forces hotter air down and hinders it from going up, thereby reducing heat stratification in the atmosphere. ROBUR have proved that, with series G heaters in operation, the difference between the temperatures at the height of 1 and 6 m is 1.5 °C only: the temperature at the height of 1 m is 19 °C, meanwhile, that at the height of 6 m is 20.5 °C (see Fig. 2). The pyramid-shaped heat exchanger from ROBUR is also distinguished for the better preheating of the whole air stream produced by the fan. This is due to a special design of the heat exchanger which facilitates minimum clearances in-between heating plate-fins (see Fig. 3). The area of the surface of the heat exchanger is significantly larger than that of standard heat exchangers: in the inside, the exchanger has aluminum alloy fins arranged in a vertical circle which (fins) are passed by flue gas (combustion products), and on the outside, it has aluminum alloy plates arranged horizontally around it to render some additional area for heating of ambient air (see Fig. 4). All in all, we have a compact unit with a smaller, however, more effective heat exchanger capable of producing more heat.

Fig. 3: ROBUR heat exchanger profile

Fig. 2: Average air stratification, upon three types of gas systems compared

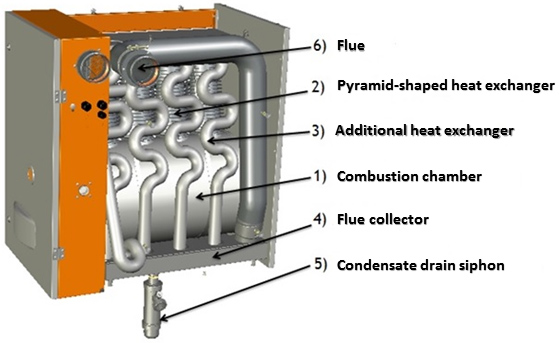

What is the principle of operation of series G gas fired unit heaters from ROBUR? First of all, an inlet fan turns on and the best gas-to-air ratio is mixed in a special combustion pipe (Pre-Mix). An electrode ignites the air-gas mixture; this produces a long and even flame which is burning all over the drum-shaped part of the heat exchanger (1). Then, the heated up gas (the heat from the burning process) travels upwards by warming up the special part of the pyramid-shaped heat exchanger (2). This is the main part of the heat exchanger thanks to which an air stream is divided to different temperature layers (higher temperature at the top, lower – at the bottom). Before the flue gas is exhausted, it has to pass the additional third part of the heat exchanger (3) by warming such up. An axial-flow fan evenly blows the heat off the heat exchanger over to the premise through an adjustable grille. Any condensate is collected by a steam trap (4), and the special condensate escape syphon (5) removes the accumulated liquid from the heater. Once cooled down, combustion products are exhausted through a flue duct (6).

Fig. 4: The inside of ROBUR G heater (rear view)

Series G gas fired unit heater is special because it has an additional condensing heat exchanger. Here, combustion products are cooled down to the maximum possible degree before entering the flue gas exhaust system – the flue duct / air duct. This way, maximum quantity of heat is supplied to the premise, and only a small part thereof is released with flue gas.

Unlike any of the best available on the market condensation boilers, series G gas fired unit heaters do not require a water distribution system which renders better general efficiency of the system. They do not need any central heating system either, so their installation costs are lower. Thanks to the support brackets, heaters are installed just over the floor, in the room that needs to be heated – no area of the flooring is occupied.

Series G modulating gas fired unit heater is the newest solution for effective heating of commercial and production premises. The heaters are autonomous units subject to full modulation; the amount of energy consumed by them is that required at the particular moment only. Series G gas fired unit heaters have no inertia; they will provide the required amount of heat in just half an hour and, then, will keep such at the same level only. In respect of the price and quality, ROBUR G is the best solution with minimum gas consumptions and a quick pay-off period!

The advantages of series G modulating gas fired unit heaters:

- The Italian Company ROBUR is one of the most reliable heating companies in Europe engaged in scientific researches, seeking innovations, showing its concern about employees and respecting the environment. ROBUR offers solutions which facilitate energy efficiency and help reduce the negative effect on the environment.

- Full modulation – the heating power can be set at 40% to 100%, and the speed of the fan can be adjusted at any of the 3 available levels. Using a digital chronothermostat in a premise, the heater is capable of identifying the effective indoor temperature and to duly modulate the heating power as well as the air blow to ensure comfortable temperature in the premise under any heater operation conditions.

- Heat exchangers with Ground Effect. The patented pyramid-shaped heat exchangers in aluminum alloy reduce heat (air) stratification in a premise: thanks to them, the difference between temperatures at different levels is small. The area of the surface of such heat exchanger is significantly larger than the area of standard heat exchangers which allows transmitting a larger amount of heat.

- Pre-Mix burners from stainless steel represent the new (improved) burner technology that produces a long and even flame which improves temperature distribution within a heat exchanger. The burner is controlled by an advanced microprocessor which allows the best gas-to-air ratio under any working conditions, and reduces CO and NOx emissions down to the minimum at the same time. In addition, regulation of the pre-mix allows preventing problems in the exhaust system.

- Quality guarantee – this is a European product with 100% of its manufacture done in Italy. Its technical parameters meet the declared values, as provided for in CE certificate. All the heaters from ROBUR have been certified for C type installation. This means that the combustion circuit is completely isolated, and all combustion products are exhausted to the outside. The heaters are made from premium quality components (steel casing coated in epoxy powder, axial-flow fan, burner from stainless steel, heat exchanger in aluminum alloy, drum-shaped heat exchanger from stainless steel).

- Compact, easy to install. One of the best heaters available on the market based on the power-to-weight ratio. Low installation and time costs.

- A recirculation chamber can be connected to supply fresh air.

- Extensive application: workshops, factories, warehouses, car showrooms and washes, garages, logistics centers, gyms and fitness centers, exhibition areas and conference halls, shopping malls, churches, laboratories, greenhouses, indoor tennis courts, bowling alleys and other commercial as well as industrial buildings of medium or large area.

Each condensing G Series heater is equipped with:

Each condensing G Series heater is equipped with:

- digital remote control (control, setting and diagnostic of functioning);

- condensate drain siphon;

- LPG kit;

- wall template;

- use and maintenance manual of the heater.

The company was offered a modern, energy efficient heating solution increasing the level of comfort both for people and the environment. Two especially efficient modulating gas fired unit heaters ROBUR G have been installed. The heaters warm up the hangar within short period of time and keep the air temperature at +21°C. Series G gas fired unit heaters use energy when needed only, an additional condensation heat exchanger ensures maximum outlet of heat to the premises, so, therefore, gas consumptions are very low. The unit is also provided with additional recirculation chambers which allow the supply of fresh and warm air. At the top, underneath the ceiling, LEO D destratificators have been installed. The latter reduce the difference between temperatures at different levels to the maximum degree, prevent warm air from accumulating at the top and distribute such evenly over the premise. In summer time, LEO D destratificators are used to improve air circulation.

Heating equipment

Heating equipment Fan water heaters

Fan water heaters Gas heaters

Gas heaters Air curtains

Air curtains Hot water

Hot water Ambient

Ambient Gas fired

Gas fired Fan coils

Fan coils Wall mounted

Wall mounted Concealed

Concealed External gas heaters

External gas heaters Infrared heaters

Infrared heaters Electric

Electric Gas - radiant tube

Gas - radiant tube Heat pumps

Heat pumps Gas

Gas Destratification fans

Destratification fans Gas radiators

Gas radiators Gas boilers

Gas boilers Electric heaters

Electric heaters Diesel fired heaters

Diesel fired heaters Containers and drums heating

Containers and drums heating IBC containers heaters

IBC containers heaters Drum heaters

Drum heaters Gas cylinders heaters

Gas cylinders heaters Heating blankets and mats

Heating blankets and mats Ventilation equipment

Ventilation equipment Ventilation components

Ventilation components Anemostat diffusers

Anemostat diffusers Air grilles

Air grilles Wall grilles

Wall grilles Air-flow grilles

Air-flow grilles Floor air grilles

Floor air grilles  Doors air grilles

Doors air grilles Spiral grilles

Spiral grilles Egg crate grille

Egg crate grille Pressed air grilles

Pressed air grilles Metal-mesh air grilles

Metal-mesh air grilles Perforated air grilles

Perforated air grilles Low-velocity diffusers

Low-velocity diffusers Louvre systems / Regulating louvres

Louvre systems / Regulating louvres External intake louvres

External intake louvres External exhaust louvres

External exhaust louvres Roof units

Roof units Intake & Exhaust louvres

Intake & Exhaust louvres Roof bases

Roof bases  Cylindrical roof exhaust

Cylindrical roof exhaust  Under-window air valves

Under-window air valves Plenum box

Plenum box Dampers

Dampers  Duct dampers

Duct dampers  For grilles & diffusers

For grilles & diffusers Fans

Fans Roof mounted extraction fans

Roof mounted extraction fans Wall mounted extraction fans

Wall mounted extraction fans Smoke extraction fans

Smoke extraction fans Ducted fans

Ducted fans Cooling equipment

Cooling equipment Evaporative air coolers

Evaporative air coolers Dry coolers

Dry coolers Remote condensers

Remote condensers